Increased wear resistance and resistance to thrombosis

Essential in the design of the CardiaMed valve, was the surgeons’ request to use solid pyrolytic carbon for both the leaflets and the housing of the valve instead of a thin carbon coating. CardiaMed produces the Solid Pyrolytic Carbon in-house. The solidity and isotropy of this nanocomposite allows manufacturing of valve parts with 1 micron precision, without compromising the strength of the material. The solidity of the leaflets and housing prevents variable thickness of the material that occurs with carbon coating. The CardiaMed valve provides unmatched strengths and durability. The unmatched smoothness of the surface lowers the risk of thrombosis.

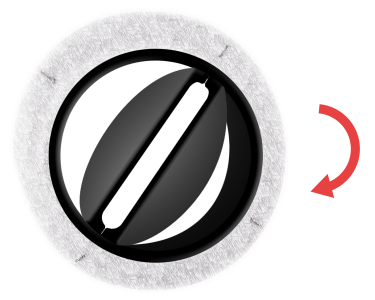

Controlled backflow

The optimised hemodynamic profile of the leaflets:

- Creates a smoothly spreading blood flow

- Prevents blood flow turbulence

- Assures rapid valve opening and closure with an opening angle of the leaflet of 85 degrees

- Soft closing of the leaflets, reducing noise.

The back-flow of the CardiaMed valve has been a major part in the design of the valve. The valve generates a controlled regurgitant blood flow that consists of 4 powerful, intended and controlled jet streams.

SIZES

-

25

-

27

-

29

-

31

-

33

Reviews

There are no reviews yet.